Here are some general methods that cutting machines might employ to handle changes in cardboard thickness:

- Adjustable Cutting Parameters: Many cutting machines allow operators to adjust cutting parameters such as cutting speed, cutting force, and blade depth. By modifying these parameters based on the thickness of the cardboard being processed, operators can optimize cutting performance and ensure clean, accurate cuts.

- Automatic Thickness Detection: Some advanced cutting machines are equipped with sensors or systems that automatically detect the thickness of the material being fed into the machine. Based on this information, the machine adjusts its cutting parameters accordingly to ensure optimal cutting results.

- Pressure-Sensitive Cutting: Certain cutting machines feature pressure-sensitive cutting mechanisms that adapt to changes in material thickness by applying variable cutting pressure. This ensures consistent cutting performance across different thicknesses of cardboard without requiring manual adjustments.

- Multi-Stage Cutting: In cases where the cardboard thickness varies significantly, some cutting machines may employ multi-stage cutting processes. tent pvc fabric cutting machine This involves multiple passes of the cutting tool at different depths to ensure thorough cutting through the entire thickness of the cardboard.

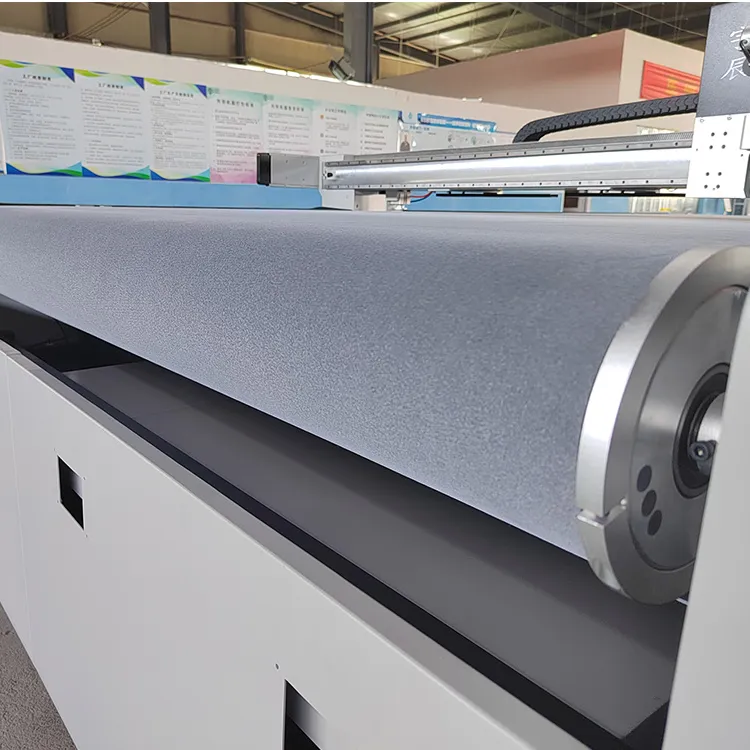

- Material Handling Systems: Cutting machines may incorporate material handling systems such as adjustable feed rollers, conveyor belts, or vacuum tables to accommodate changes in cardboard thickness and ensure proper material alignment and stability during cutting.

- Operator Monitoring and Adjustment: In some instances, operators may need to manually monitor the cutting process and make adjustments to the machine’s settings based on changes in cardboard thickness. This may involve visual inspection of cut samples or periodic measurements of cardboard thickness to ensure consistent cutting performance.

Overall, handling changes in cardboard thickness during production requires a combination of adaptable cutting mechanisms, advanced sensing systems, and operator expertise to ensure optimal cutting results and productivity. Each cutting machine may utilize different approaches depending on its design, capabilities, and intended application.