To create interlocking blocks and also bricks you need to prepare aggregate, water, and powdered concrete. Then you need to blend them with a specific ratio used for this purpose. Typically, one system of concrete is blended with 4 systems of accumulation. Afterwards, you will include water to have your mortar. Because this mortar is different from the mortar prepared in batching plants, be careful not to include much water.

After the mortar preparation, you need a mold and mildew and also enough pressure on the mold and mildew to shape the mortar. For this objective there are a lot of alternatives, you can utilize little manual makers, hydraulic presses, or automated interlocking block machines in high abilities.

When the mortar has formed in the form of the mold and mildew, it is delivered to the curing area where it is left for 18 to 24 hours to dry out up. Typically, it is watered every 6 hrs to make it stronger and extra long lasting.

After the healing time, you can utilize your interlocking blocks according to their style. This can be on a wall, paver, or perhaps roofing systems.

Interlacing Block advantages

Interlocking blocks are the same as concrete blocks however they have their unique form. Interlocking blocks can lock each other because of their special layout. This is beneficial in numerous methods.

- Because they lock each other without any type of mortar made use of, less mortar is utilized in between the blocks.

- The construction rate will be a lot more than normal blocks.

- The interlocking blocks develop a much more powerful surface than normal blocks.

- Since of the reduced man-hours, they reduce the complete price of a completed wall or paver.

Interlocking Block Machine

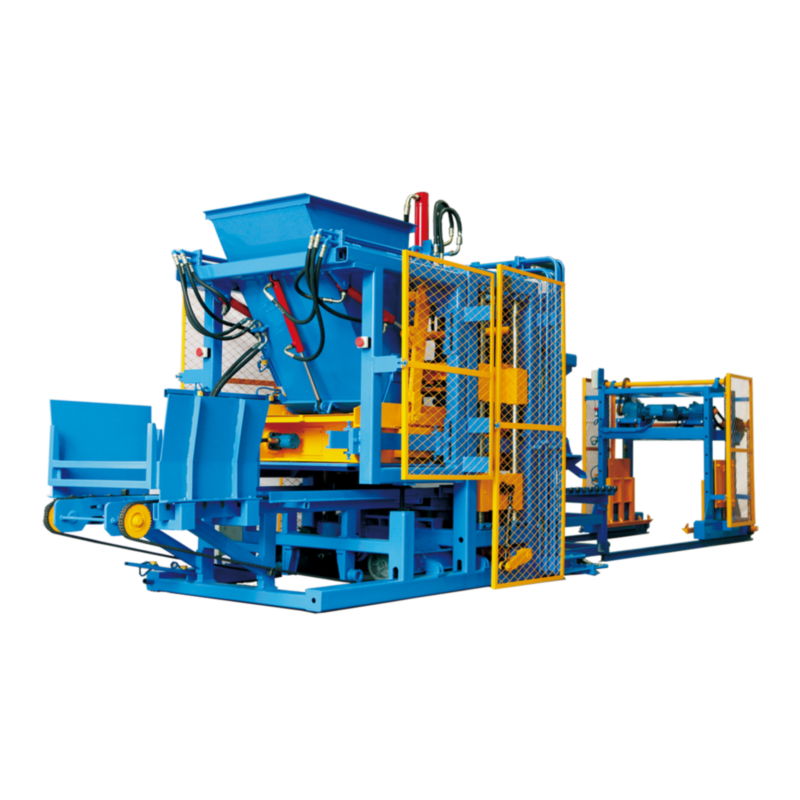

Interlacing block machines are the devices with solitary receptacles. These devices can produce hollow blocks, strong blocks, curbstones, and single-layer paving blocks. , if you desire to generate tinted blocks you need to use the color to the whole block.

Interlacing block machines are generated in 3 different automation degrees which are defined in the adhering to areas.

The interlocking block machines are also called hollow block machines.

These equipments can produce hollow blocks, solid blocks, curbstones, and double-layer paving blocks. With these interlocking brick makers, you can use color mortar only to the leading layer of the paving block.

You can additionally use smaller sized aggregates to the leading layer to have a smoother surface.

The interlocking brick equipments are likewise called paver block machines.

Consider that in many countries in the globe paving blocks are called interlocking blocks. These interlocking blocks have different shapes and also sizes and thicknesses.

Interlocking block machines are manufactured in mobile as well as fixed types. Consider that Bess produces these makers completely plant variations. This implies these machines are used as a set consisting of the aggregate hoppers, conveyor belts, mixer, interlacing block machine, and also other devices required for generating interlocking blocks.

- Semi-automatic interlocking block device:.

The semi-automatic interlocking block machines are the smallest makers in this group. The minimum capacity of these devices is 4000 interlocking blocks or 300 m ² of interlacing paving blocks in one shift. After the manufacturing, the pallets are transported to the healing location by handcarts. You entirely need 7 workers for this kind of plant.

- Automatic block equipment:.

Automatic interlacing brick equipments are practically the same devices as the semi-automatic type with a significant distinction, loader and also unloader robotics are utilized on the makers. This suggests you need a forklift instead of handcarts to deliver the pallets to the treating location.

In this method, you only need one employee for transportation as well as you likewise need a smaller curing area for your plant. Totally you need 5 employees for the automatic plants.

- Totally automatic block making machine:.

These makers are supplied in high abilities and they are supplied as complete plants, you only require 2 workers to run your whole plant. A lot of the work is done by china block making machine robotics in this kind of plant. Keep in mind that totally automatic interlocking block machines are one of the most costly alternative, however if you stay in a nation with high labor prices as well as expensive land, this choice is ideal for you.

If you are interested in beginning your interlocking block manufacturing plant and also you don’t recognize which equipment is the most effective option for you, you can ask our sales department to help you pick the ideal equipment. Bess business is a well-known brand name in the concrete block device production industry. With more than 420 functioning makers in greater than 38 nations, our sales department can suggest to you the best option based upon your preferred ability, your land, as well as your spending plan.

You also require to think about labor costs in your country. You better choose a semi-automatic equipment with greater capacity instead of picking a low-capacity little device if you are living in a nation where labor price is cheap. if you really feel baffled as well as thinking about getting professional assistance you can contact us at any time. Our get in touch with information are available at the end of this write-up.

Interlocking Block Device Working Process.

The video clip listed below programs the working process of the automatic interlocking block maker.

You can visit Bess Equipment EN for semi-automatic types or double hopper variations.

Final thought.

A lot of the moment clients are confused by the various sorts of equipments in the market with various brands and various working systems. Bess makes various interlocking block machines based on European criteria. All the devices made use of on the Bess devices is German brands.

Bess offers two years of guarantee for its interlacing block machines too. If you do not recognize which machine fits you the most effective you can contact our English department. Our seasoned sales reps will certainly assist you select the very best maker based on your task.

Interlocking blocks are the exact same as concrete blocks however they have their unique shape. Interlocking block machines are the equipments with single hoppers. These makers can generate hollow blocks, strong blocks, curbstones, as well as single-layer paving blocks. These equipments can produce hollow blocks, solid blocks, curbstones, and also double-layer paving blocks. Take into consideration that in several nations in the globe paving blocks are called interlacing blocks.