Learn about the importance of hot piercing, rotary piercing, and elongation in achieving seamless pipe integrity. Understand the heat treatment and finishing processes that enhance the mechanical properties and surface quality of seamless steel pipes.

Introduction:

The manufacturing process of seamless steel pipes is a complex and precise operation that involves several essential steps. This article serves as a comprehensive guide to the seamless steel pipe manufacturing process, providing insights into each stage of production.

From raw material selection to final inspection, businesses can gain a deeper understanding of the procedures involved in creating high-quality seamless steel pipes. By optimizing the manufacturing process, companies can produce durable and reliable pipes for various industrial applications.

What is the Seamless Steel Pipe Manufacturing Process?

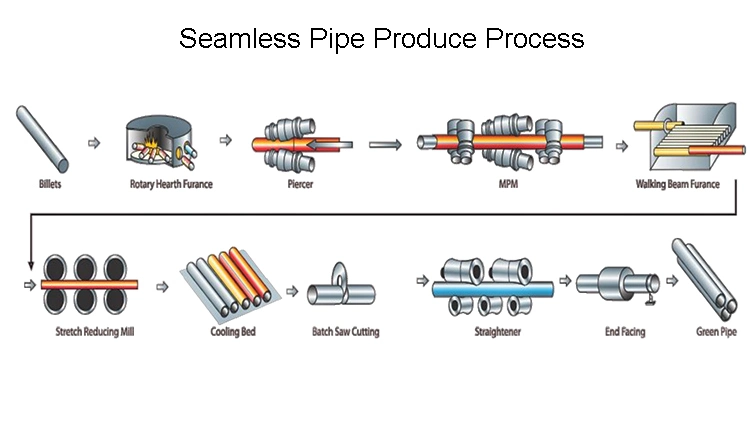

The seamless steel pipe manufacturing process refers to the method of producing pipes without welding seams. It involves several key steps, including raw material preparation, pipe formation, heat treatment, and finishing. Each stage is crucial in ensuring the integrity, strength, and quality of the seamless steel pipes.

Raw Material Selection and Preparation

The first step in the seamless steel pipe manufacturing process is the selection of high-quality raw materials. Typically, seamless pipes are made from carbon steel, stainless steel, or alloy steel. The raw materials undergo inspection, testing, and quality control measures to ensure their suitability for pipe production. After verification, the raw materials are prepared through processes such as heating, descaling, and cutting.

Pipe Formation: Hot Piercing and Rotary Piercing

The pipe formation stage involves two primary methods: hot piercing and rotary piercing. Hot piercing involves heating the prepared billet and piercing it with a piercing mill to create a hollow shell. Rotary piercing, on the other hand, utilizes a rotating mandrel and piercing rolls to achieve a seamless pipe with precise dimensions and wall thickness. These processes are critical in ensuring the integrity and uniformity of the pipe structure.

Elongation and Sizing

Following the piercing process, elongation and sizing operations are performed to further refine the pipe dimensions. Elongation involves elongating the pierced shell using a push bench or a stretch reducing mill. This process enhances the mechanical properties and reduces wall thickness variations. Sizing, which is done using a sizing mill, ensures accurate outer diameter and wall thickness according to specifications.

Heat Treatment and Finishing

Heat treatment is a vital step in the manufacturing process to enhance the mechanical properties of seamless steel pipes. Processes such as annealing, normalizing, or quenching and tempering are employed to achieve desired strength, hardness, and toughness. After heat treatment, the pipes undergo finishing operations, including straightening, cutting, and surface treatment. These processes ensure precise dimensions, smooth surfaces, and corrosion resistance.

Final Inspection and Quality Assurance

The final stage of the manufacturing process involves comprehensive inspection and quality assurance. The seamless steel pipes undergo various tests, including dimensional checks, visual inspection, non-destructive testing, and mechanical property evaluation. These rigorous inspections guarantee that the pipes meet the required standards and specifications. Only after passing the inspection, the pipes are ready for packaging, storage, and distribution.

Conclusion:

The seamless steel pipe manufacturing process involves a series of precise and critical steps to produce high-quality pipes. From raw material selection to final inspection, each stage plays a significant role in ensuring the integrity, strength, and reliability of the pipes. By understanding the intricacies of this manufacturing process, businesses can optimize their production and deliver seamless steel pipes that meet the stringent requirements of various industries. Embrace the insights gained from this comprehensive guide and excel in seamless steel pipe manufacturing.