Filter press plate is a critical component in filter press operations, used for solid-liquid separation in various industries. This article provides a comprehensive guide on filter press plates, including types, materials, and applications. Whether you are new to filter press or an experienced operator, this guide will help you understand everything you need to know about filter press plates.

Introduction to Filter Press Plate

Filter press plate is a crucial component in filter press operations, used for separating solid particles from liquid in various industries such as mining, chemical, pharmaceuticals, food, and beverage. This article provides a comprehensive guide on filter press plates, including types, materials, and applications.

Types of Filter Press Plate

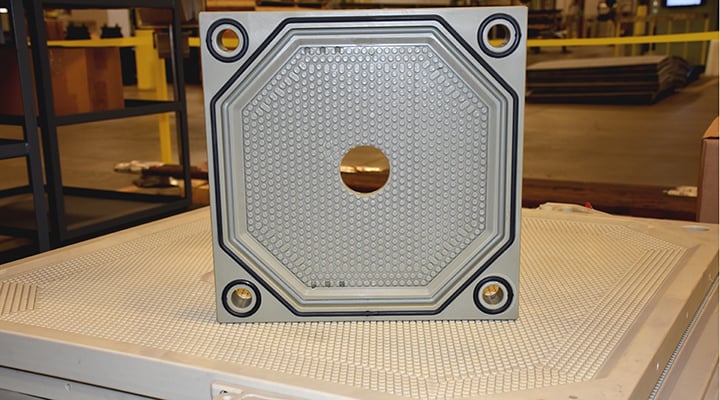

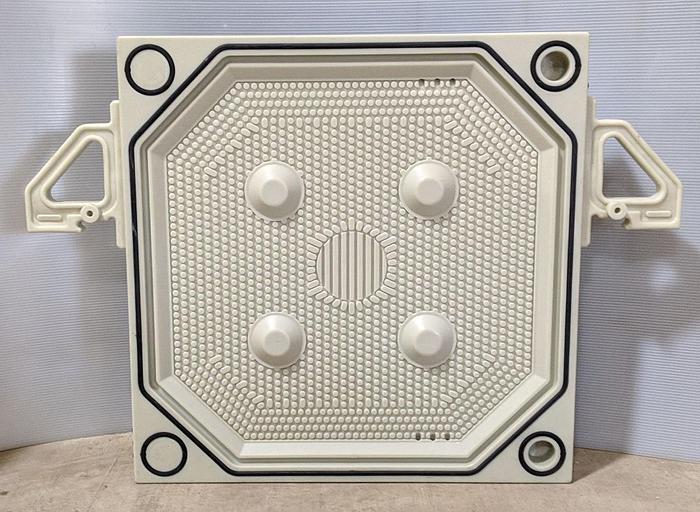

There are three main types of filter press plates: recessed chamber, diaphragm, and plate and frame. Recessed chamber plates are commonly used in filter presses and are designed to create a chamber that holds the solid particles. Diaphragm plates have a flexible membrane that expands and contracts under pressure, while plate and frame plates consist of a series of frames and plates that hold the filter cloths.

Materials of Filter Press Plate

Filter press plates can be made of various materials, including polypropylene, stainless steel, cast iron, and aluminum. Polypropylene plates are lightweight, corrosion-resistant, and easy to clean. Stainless steel plates are durable, high-temperature resistant, and suitable for corrosive environments. Cast iron plates are cost-effective and suitable for high-pressure applications, while aluminum plates are lightweight and suitable for low-pressure applications.

Applications of Filter Press Plate

Filter press plates are used in various industries, such as mining, chemical, pharmaceuticals, food, and beverage, for solid-liquid separation. They are used to filter slurry, wastewater, and other liquids containing solid particles. Examples of applications include dewatering mining concentrates, filtering wine, and processing sugar syrups.

Advantages and Disadvantages of Filter Press Plate

Filter press plates offer many advantages, including high filtration efficiency, low operating cost, and easy maintenance. However, they also have some disadvantages, such as high initial cost, limited capacity, and susceptibility to fouling.

Maintenance of Filter Press Plate

Proper maintenance of filter press plates is essential for optimal performance and longevity. Regular cleaning, inspection, and replacement of damaged plates are necessary to avoid downtime, reduce operating costs, and ensure product quality.

Conclusion

Filter press plate is a critical component in filter press operations, used for separating solid particles from liquid in various industries. This article provided a comprehensive guide on filter press plates, including types, materials, and applications. By understanding the different types of filter press plates, their materials, and their applications, operators can select the best filter press plates for their specific needs and optimize their filter press operations.